extends from consulting on the CAD construction of the tools to the complete tool shop with subsequent production of the desired components. The long-term experience of our employees in combination with state-of-the-art machine technology guarantee quality, reliability and constant readiness to improve the process sequences.

A comprehensive range of services and a corresponding customer service perfectly complete the spectrum.

Stamping, forming and thermoforming

For all industry areas, various metal parts of all sizes are produced on our individual presses or punching machines. From bent, punched parts made of stainless steel with a thickness of 0.2 mm up to boards, e.g. copper strips with a material thickness of 8 mm, we will work out the best and most economical concept for you, according to your desired quantity and wishes, right up to the packaging and transport. In order to fulfill the complete offer, we also manufacture various deep drawing parts in series. From windows for fans to small sockets for heat meters, there are no limits. Together with our sister company Integral Metalltechnik, we have several punching machines with a pressing force of 30 tons going up to 630 tons of pressing force at our site, so that you can also ask for all possibilities of different component sizes.

Surface treatment

For this purpose, we also have a lot available in our machine park to offer our customers the complete one-piece punched part. Several Trowal systems from the company Rösler with various stones for the processing of the punching burr on the component, as well as a steam degreasing system is available to guarantee the appropriate cleanliness or the desired surface tension on the component. In order to be able to request all common coatings on the components for our customers, we only work with our qualified suppliers.

Welding, assembly work, assembly manufacturing

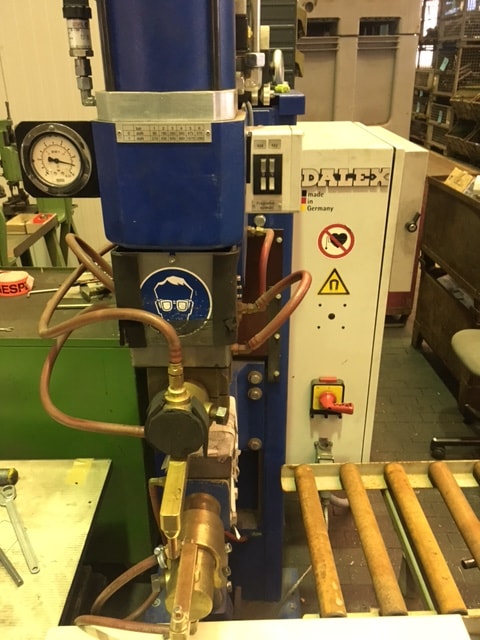

The use of state-of-the-art robot welding systems and the use of various welding methods, in particular spot and TIG welding, as well as laser MIG and MAG welding, can be used to precisely match the most varied material types. In many cases, by dividing complex components into individual components, it is possible to save up on materials (for example, sliding frames), thus ultimately reducing costs for the customer.

Also available in our partial spectrum, in order to be able to connect the desired components together.

We can process or press the riveting of punched parts or nuts as well as desired bolts in assemblies for you.

Tool Fabrication

In order to achieve the highest possible quality standards is the use of suitable tools is decisive. In particular, the adherence to dimensional accuracy along the entire product life cycle is of crucial importance. To ensure this, the company MAHR Metalltechnik, together with its sister company Integral Metalltechnik, offers its customers the development and manufacturing of suitable tools.

Lasering + Edges

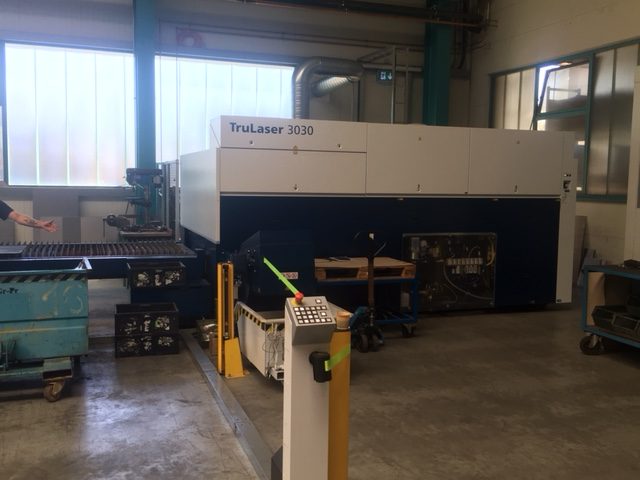

Trumpf 3030 Fiber Laser with Trumpf Liftmaster

In the field of laser technology, a new fiber laser (TruLaser 3030) from Trumpf, including the associated Liftmaster, was put into operation in March 2016. With this laser technology, we can also cut high-gloss material such as pure aluminum Al 99.5.

Water Jet Cutting

5Achs jet of water guts arrangement Löffler Power jet in 2011

Now by the investment in the new manufacturing area of the jet of water guts technology we are able to cut the most different materials non-polluting and exactly.

By the 5-axes technology it is possible for us to generate 3-D cut edges.